A key process in modern manufacturing

Plastics processing is a collective term for the techniques and processes used to shape plastic materials into finished products or components. It is a central part of today's manufacturing industry – from simple plastic packaging to advanced parts in vehicles and medical equipment. But what exactly is plastics processing?

In this article, we review the basics of plastic processing, its historical background, common methods, material choices, and which industries rely on the technology. We also highlight how processing has evolved towards more sustainable solutions – and why companies like MK Plastteknik are important players in the field.

What is plastic processing?

Plastics processing encompasses various techniques for transforming raw plastic materials into finished objects. It can involve everything from melting and injecting plastic into molds to milling, bending or vacuum forming plastic sheets into complex parts.

Unlike metalworking, which often requires high heat and robust tools, plastic machining is generally more flexible, allowing for the creation of lightweight, durable and cost-effective solutions. It is this adaptability that makes plastic such a popular material in a variety of industries.

The history of plastics – from innovation to industry

Polymers such as rubber were used as early as the 16th century, but it was not until the 19th century that the first synthetic plastics began to be developed. In the mid-1860s, nitrocellulose, called parkesin, was invented, which is considered the first commercially useful plastic.

The use of plastics exploded in the 20th century, especially during World War II, when the material was used in everything from military equipment to communication systems. After the war, plastics became a symbol of progress, modernity and mass production. Today, the processing method has become a specialized industry where technology, precision and sustainability are at the center.

Common methods in plastics processing

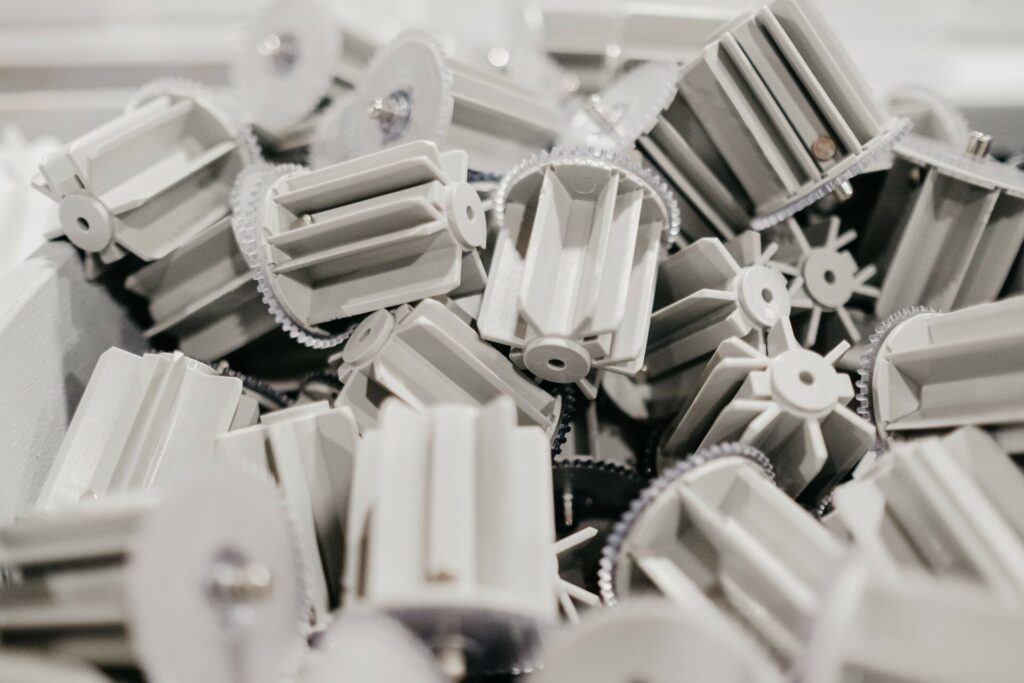

Injection molding: Injection molding is the most widely used method in plastic processing for mass production. Here, the plastic is melted and injected under high pressure into a mold, where it then solidifies.

Vacuum forming: Vacuum forming involves heating a plastic sheet until it becomes malleable and then sucking it over a template using a vacuum.

CNC machining: CNC machining is often used to fräsa or turn plastic parts with high accuracy. This method is particularly suitable for prototypes, small series and components where dimensional accuracy requirements are high.

Bending: Bending used to shape plastic at various angles, often in the manufacture of signs, panels or other visual products.

Here you can explore which services we work with in plastic processing!

Material selection in plastics processing

The choice of plastic material not only affects the properties of the product, but also the method used in processing. Some common types of plastic include:

- Polyethylene (PE): Soft, flexible and chemical resistant.

- Polypropylene (PP): Durable and heat-resistant.

- Polystyrene (PS): Rigid and easy to process.

- Polycarbonate (PC): Extremely impact-resistant and transparent.

- Acrylic (PMMA): UV-resistant and clear.

Advantages of plastic processing

- Cost efficiency: Low material cost and efficient production.

- Design flexibility: Ability to create complex shapes and structures.

- Design flexibility: Ability to create complex shapes and structures.

- Corrosion resistance: Plastic is resistant to many chemicals and moisture.

Environmental aspects and sustainability

I takt med att miljöfrågor blivit allt viktigare har plastindustrin börjat ställa om mot mer hållbara lösningar. Återvunnen plast används i allt större utsträckning, och bioplaster utvecklas som alternativ till oljebaserade material. MK Plastteknik arbetar aktivt med hållbara metoder och energieffektiva produktionsprocesser. Genom smart materialanvändning och teknisk expertis kan vi erbjuda lösningar som möter både kundens behov och miljökrav.

Are you in need of advanced plastic processing? MK Plastteknik offers comprehensive services in plastic processing, including injection molding, vacuum forming and CNC machining. With over 20 years of experience, we guarantee high quality and precision in every project.

MK Plastteknik – Experts in plastic processing since 2001.